When it comes to custom apparel printing, Direct-to-Garment (DTG) and screen printing are two of the most popular methods. Each offers unique benefits and is suited to different needs, but durability is often a key factor for businesses and consumers when choosing between them. This article explores the durability of DTG and screen printing, providing insights into how each method holds up over time and use.

Understanding DTG Printing

Direct-to-Garment printing is a modern technique that involves applying ink directly onto fabric using specialized printers. The process is similar to how an inkjet printer works, with inks absorbed into the fibers of the garment. DTG is favored for its ability to produce highly detailed, full-color designs, making it ideal for short runs and intricate artwork.

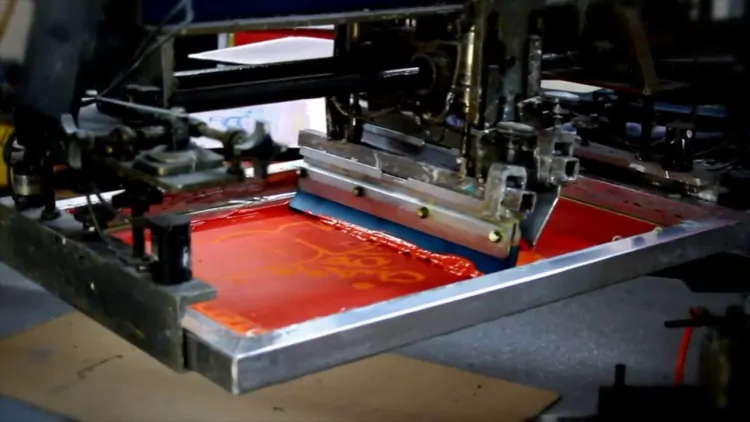

Understanding Screen Printing

Screen printing, one of the oldest printing methods, involves pushing ink through a stencil (screen) onto fabric. Layers of ink are applied for each color in the design, creating a vibrant and bold finish. Screen printing is renowned for its durability and cost-effectiveness, especially for large batches.

Durability of DTG Printing

-

Ink Absorption:

- DTG inks penetrate the fabric fibers, creating a smooth, natural feel. However, the depth of absorption can vary depending on the type of fabric used.

- Cotton garments are the most suitable for DTG, as the ink bonds better with natural fibers.

-

Wear and Tear:

- Over time, DTG prints may fade slightly, particularly if not cared for properly. Factors such as frequent washing, exposure to sunlight, and abrasive contact can affect the print’s longevity.

-

Care Requirements:

- DTG-printed apparel typically requires gentle care, including washing in cold water and avoiding harsh detergents. Using a dryer at high heat can accelerate fading.

-

Lifespan:

- DTG prints can last for several years with proper care, but they are generally less durable than screen prints, especially for designs with heavy ink coverage.

Durability of Screen Printing

-

Ink Thickness:

- Screen printing uses thicker layers of ink compared to DTG, resulting in a bolder and more durable design. The ink sits on top of the fabric rather than being absorbed, creating a robust and long-lasting print.

-

Resistance to Wear:

- Screen-printed designs are highly resistant to cracking, peeling, and fading, even after numerous washes. This makes them ideal for heavy-use items like uniforms, sportswear, and promotional T-shirts.

-

Versatility in Fabrics:

- Screen printing works well on a variety of fabrics, including cotton, polyester, and blends, without compromising durability.

-

Care Requirements:

- While screen-printed garments are generally low-maintenance, following standard care guidelines, such as washing inside out and avoiding bleach, can extend their lifespan further.

Key Factors Influencing Durability

-

Fabric Quality:

- High-quality garments enhance the durability of both DTG and screen prints. Lower-grade fabrics may lead to faster wear and tear.

-

Ink Quality:

- Premium inks improve durability. DTG relies on water-based inks, while screen printing often uses plastisol inks, which are inherently more robust.

-

Application Process:

- Proper curing (drying) is essential for both methods. DTG prints need heat to set the ink, while screen prints require curing to bond the ink securely to the fabric.

-

Usage and Washing:

- Frequent use and improper washing can affect the durability of any print, but screen printing is more forgiving under such conditions.

Which Method is More Durable?

In terms of sheer durability, screen printing has a clear advantage. Its thicker ink application and resilience against wear make it a preferred choice for garments intended for heavy use. On the other hand, DTG printing excels in producing detailed and colorful designs, but its durability depends heavily on fabric type and care.

Choosing the Right Method

-

Screen Printing:

- Best for bulk orders, simple designs, and garments that will see frequent or rugged use.

- Ideal for businesses, sports teams, and promotional items.

-

DTG Printing:

- Perfect for small runs, detailed artwork, and one-off designs.

- Suited for fashion brands or personal customizations where intricate graphics are key.

Conclusion

Both DTG and screen printing have their strengths, but when it comes to durability, screen printing is the more robust option. For designs that need to withstand heavy use and frequent washing, screen printing delivers unmatched longevity. However, for detailed, colorful, and small-batch projects, DTG offers unparalleled convenience and visual appeal.

Understanding your specific needs, including design complexity, fabric type, and intended use, will help you make the best choice between these two popular printing methods.